The type and rate of degradation and the performance rankings produced in exposures to fluorescent UV lamps can be much different from those produced by exposures to other types of laboratory light sources. Do not place the apparatus near a heat source such as an oven. Rubber Testing Machine All references to exposures in accordance with this practice must include a complete description of the test cycle used. Up to 20 test samples are mounted in the QUV and subjected to a cycle of exposure to intense ultraviolet radiation followed by moisture exposure by condensation.

| Uploader: | Mikakora |

| Date Added: | 17 April 2013 |

| File Size: | 11.37 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 85063 |

| Price: | Free* [*Free Regsitration Required] |

This practice is intended to induce property changes associated with end-use conditions, including the effects of sunlight, moisture, and heat. Historical Version s - view previous versions of standard.

Turn the device d44587 before removing panels for inspection.

When a single exposure period is used, select a time or radiant exposure that will produce the largest performance differences between the test materials or between the test material and the control material. Note 1—Previous versions of this practice referenced fluorescent UV devices described by Practicewhich described very specific equipment designs. The heating mode adopts inner bladder trough type heating with its rapid temperature rise and even temperature distribution.

B The irradiance set point given is typical for devices operated without irradiance control. Auditing Consulting Sourcing Training. Precision and Bias We can offer operation video and English operation muanual.

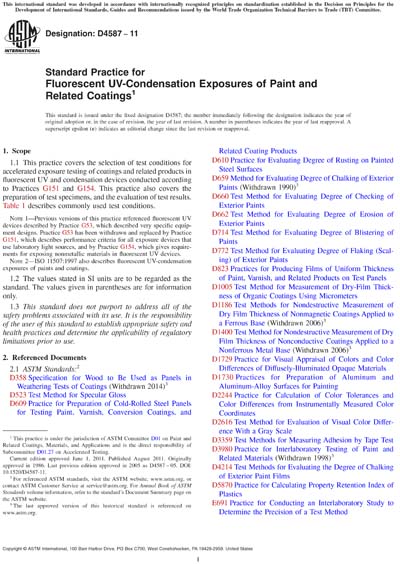

Accelerated Weathering (QUV) ASTM G154, ASTM D4329, ASTM D4587, ISO 4892

If in doubt, users should consult the manufacturer of their device for clari? Refer to Practice G for more information about the construction and e4587 between uninsulated and insulated black panels.

The measurement data used to establish these set points was inaccurate, due to an error in calibration on the part of one manufacturer.

It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

SUS steel Temperature control: Do not use this covered area of the specimen as part of the test area.

B The irradiance set point given is typical for devices operated without irradiance control. Provide reference with testing data for improvement of existing materials, or to assess the impact of changes in product durability and other aspects.

Accelerated Weathering (QUV) ASTM G, ASTM D, ASTM D, ISO

This practice also covers the preparation of test specimens, and the evaluation of test results. Link to Active This link will always route to the current Active version of the standard. All references to exposures in accordance with this practice must include a complete description of the test cycle used.

The test panels are actual the side wall of the chamber. Each set protected with resin fiber and PP film, then put into Strong wooden case with operation man Delivery Time: Work Item s - proposed revisions of this standard.

Standard UV Accelerated Weathering Tester ASTM D , Automatical PID SSR Control

G Historical convention has established this as a very commonly used test cycle. Industrial maintenance coatings G.

The measurement data used to establish these set points was inaccurate, due to astj error in calibration on the part of one manufacturer. Your comments are invited either for revision of this standard or for additional standards and should be addressed to ASTM International Headquarters.

Therefore, no reference to the use of this practice shall be made unless accompanied by a report prepared according to Section 10 that describes the speci?

SUS stainless steel Use: Guangdong, China Mainland Brand Name: Whether your business is local or global, we can ensure your d457 meet quality, health, environmental, safety, and social accountability standards for virtually any market around the world. Significant factors include regulation of line voltage, temperature of the room in which the device operates, temperature control, and condition and age of the lamps.

Send us a request Wilton UK: Note 3—Additional information on sources of variability and on strategies for addressing variability in the design, execution and data analysis of laboratory accelerated exposure tests is found in Guide G This condition requires that the procedures described in 8.

Comments

Post a Comment